- Centrifugal Fan Design software, free download Windows 10

- Centrifugal Fan Diagram

- Centrifugal Fan Design software, free download

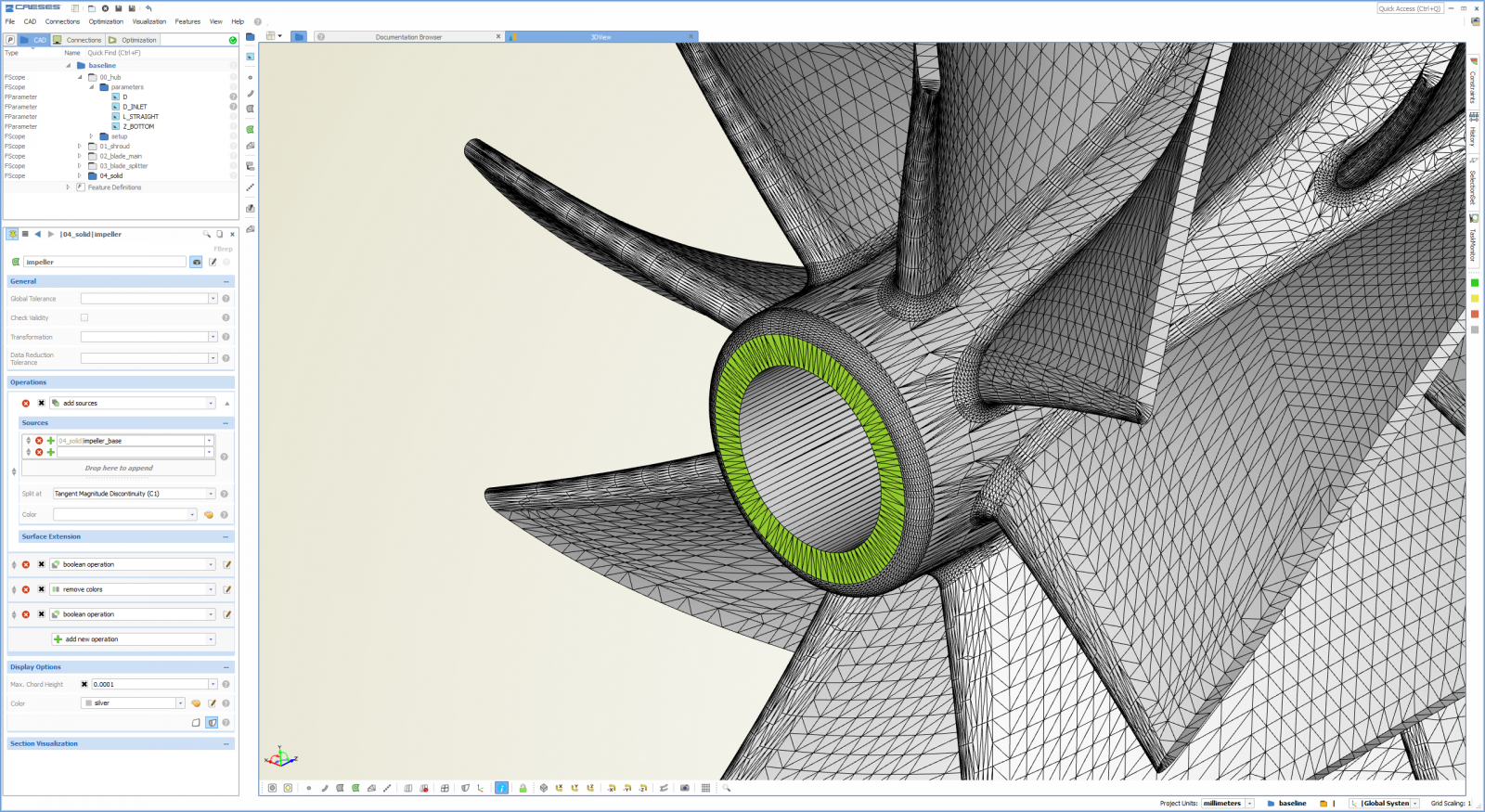

Our fan module is made for engineers who design and optimize all types of fans, blowers, and ventilators.

Anthony Hilton on BEST Centrix.fan.software.crack. H r resources centrix v390.06. Centrix is a centrifugal fan selection program. 70,000 bhp 52,200 kw steam turbine driving the cracked gas compressors in a. Centrix is a centrifugal fan selection software that helps fan manufacturers to design. LG's scroll compressors include fixed speed, two-stage, variable speed, and R1 compressor. Find out more and discover which scroll compressor is suitable for you. Centrifugal Blower Design software, free download 3/13/2018 The correlation functions used to calculate dimensional and physical parameters of each new fan have their origin in the classical theories of fluid mechanics, becoming known as the Fan Laws or Affinity Laws, while the noise predictions are based on acoustic principles. Sigma guitars serial numbers.

CFturbo supports the design of axial, mixed-flow, and centrifugal ventilators. Special types like radiator fans or squirrel-cage blowers can also be created.

LG's Commercial Laundry Systems give you a total laundry solution including the most suitable equipment and full support for your business. The centrifugal fans with backward-curved blades are designed as freewheel fans and do not require a scroll housing. In the case of centrifugal fans with external rotor motors, the motor is positioned in the impeller, ensuring not just optimum cooling of the motor, but also a particularly compact design.

Production-related simple blade forms such as circular bladed impellers can be made, as well as swept impeller blades to improve acoustic behavior.

Capabilities

- Design different types of ventilators in a specific speed range 8 < nq < 500 (EU), 400 < Ns < 22,000 (US)

- Create complete pump stages from different single components such as impellers, vaned and unvaned stators, and volutes

- Use a fully parametric geometry model of the ventilator that can be the basis for design exploration and optimization

- Export the 3D model for further applications like flow simulation (CFD), finite element analysis (FEA), mechanical design (CAD), and rapid prototyping

Impellers

Design ventilator impellers according to your specific needs. The underlying design theory is based on fundemental equations and the latest empirical correlations.

Volutes

Design the volute while the ventilator type is centrifugal. Outflow conditions of the previously designed impeller or radial diffuser are automatically taken into account.

Stators

Vaned and unvaned stators complete the flow channel of the ventilator stage. Additionally, unvaned stators may be used to prepare a model for flow simulation.

Ventilator design made easy

Vocaloid text to speech online. Register and download CFturbo software for a free trial today.

Optimize your fans and blowers

Through the connection of simulation software can be partially or completely automated your workflow to optimize your fan. This will significantly reduce development time.

Centrifugal fan design| MAJOR CENTRIFUGAL FAN PARTS |

Design requirements of a large centrifugal fan are: to meet the required flow and pressure conditions at the highest point of efficiency should be near; maximum efficiency value to be as large as some of the efficiency curve flat; pressure curve to a wide range of stability; fan of simple structure , technology is good; convenient choice of materials and accessories; have sufficient strength, stiffness, safe and reliable; running stable, low noise; adjusted performance, work adaptability; fan size as small as possible, light weight; operation and maintenance , disassemble easy transport.

However, while meeting all the requirements above, is generally not possible. In the aerodynamic performance and structural (strength, process) there are contradictions between the often, usually to seize the main contradiction solve the problem. This requires designers to choose the right design to address the principal contradiction. For example:

With the use of different fans, not the same requirement, such as public buildings used as a ventilation fan is generally used with, the most important requirement is that the general low-noise, multi-blade centrifugal fan with this feature; and require large flow The centrifugal fan is usually double-suction type; for some of the high-pressure centrifugal fan, low specific speed, the relative proportion of the leakage loss is generally larger

Fan Parts-Impeller Design

The centrifugal fans impeller have five basic blade shapes, and a number of impeller configurations (i.e) DWDI (Double width double inlet) or SWSI (Single width single inlet). The impeller design will depend on the aerodynamic duty and the operating conditions.

Blade Design

| TYPES OF BLADE DESIGN |

Backward inclined, backward curved blades

| 3D MODEL OF BACKWARD CURVED IMPELLER |

Centrifugal Fan Design software, free download Windows 10

An efficient and strong shape, this design is a cost-effective alternative to the backward curved design but with flat plate blades instead of curved. This results in a slightly lower efficiency, compensated by the easier fitting of liners.

Backward inclined, forward curved blades

Centrifugal Fan Diagram

Also termed radial tipped blades, this design reduces the potential for dust build-up on the underside of the blades in applications with moderate amounts of gas-borne dust.Aerofoil blades

| 3D MODEL OF AEROFOIL IMPELLER |

Radial blades

| 3D MODEL OF RADIAL TIP IMPELLER |

Impeller configurations

Centrifugal Fan Design software, free download

A double inlet impeller consists of two single inlet impellers back to back on the shaft sharing a common backplate, providing almost double the flow of a single inlet fan. The selection of a double inlet fan results in a smaller diameter, faster (and perhaps cheaper) machine compared to the single inlet alternative. Single or multiple stageA multi-stage fan consists of two or more impellers mounted on the same shaft. The air or gas flow passes through each one in turn, with a consequent increase in pressure